Termax is a dynamic manufacturing and engineering company specializing in metal, plastic and rubber fastening systems. It was founded by Edward Smith in 1971 and prospered through his sons Bill and Mike for many years. On July 2020, LISI Group announced the signing of an agreement to become the sole owners of Termax, allowing us to extend our global footprint in clip-fastening solutions.

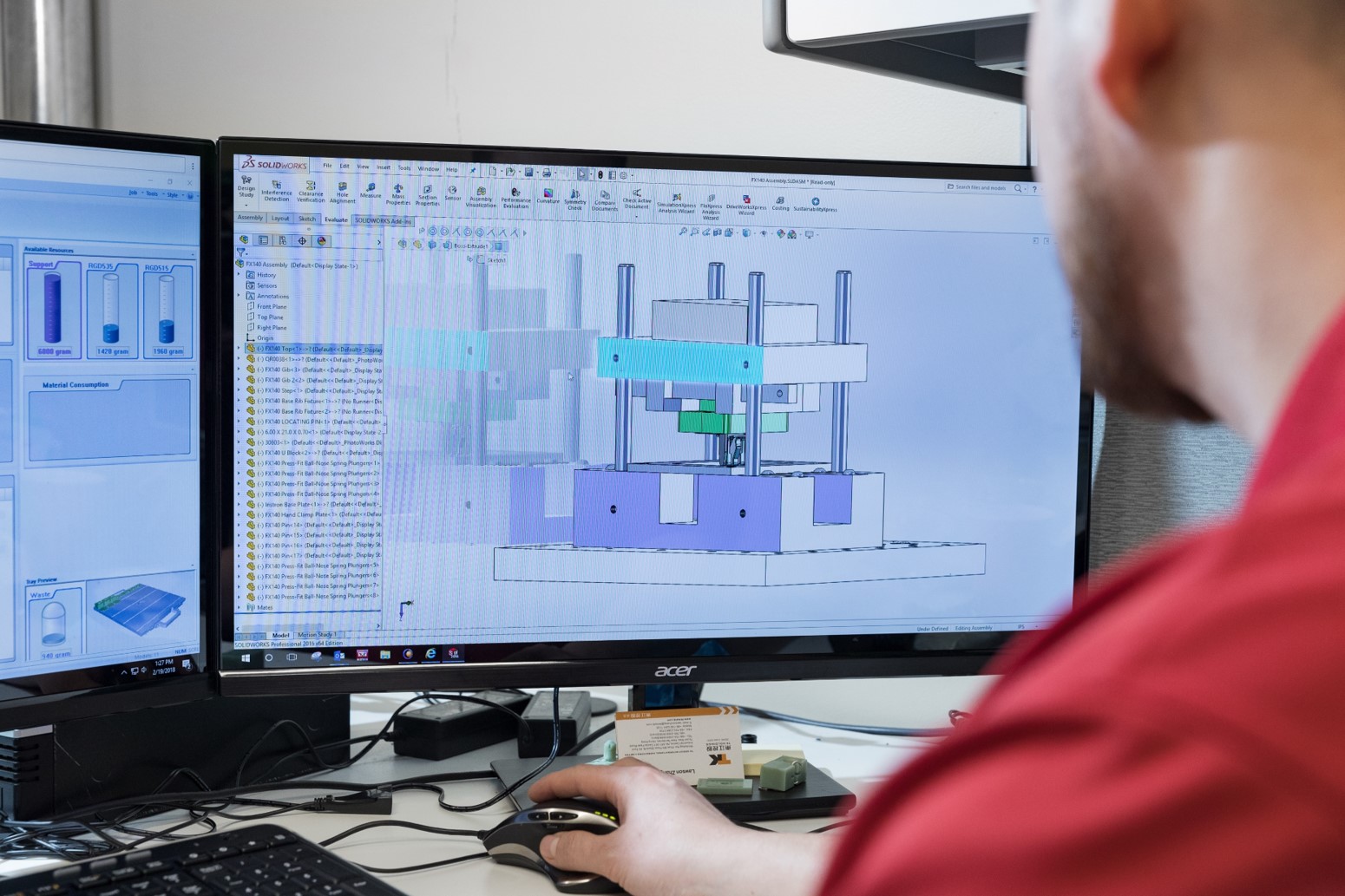

Our 120,000 square foot facility in Lake Zurich, IL, provides manufacturing, engineering and in-house tooling capabilities that world-class organizations rely on to support their operations. Our team will work with you through all phases of your project; from requirement planning, design, and engineering to tooling, manufacturing, shipping, and logistics.

Thank you for considering Termax for your fastener needs. It is an honor to have this opportunity to serve you. Please allow us to share some of our exciting problem-solving ideas with you.

QUALITY CONTROL

Termax is committed to providing our customers with defect-free products in a timely fashion at the lowest price. We make a considerable investment in advanced pieces of instrumentation to measure and observe complex shapes in parts and plating thicknesses. These devices ensure Termax product precisely meets the original design requirements.

Our Quality Certifications and Policies:

- ISO 9001:2015

- ISO 14001:2015

- ISO 45001:2018

- IATF 16949:2016

- ISO 9001:2015:MX

- IATF 16949:MX

- ISO 9001:2015:Suzhou

- IATF 16949:2016:Suzhou

- Quality Policy

- Environmental Policy

- Code of Conduct (North America)

- Code of Conduct (Mexico)

- Code of Conduct (China)

We continuously work to determine our customers’ changing requirements and develop quality procedures to meet those requirements.

We strive to achieve best-in-class quality and reliability on all products using a systematic approach that emphasizes quality at every phase of product development. From initial conception to fabrication, testing, and assembly, quality is built-in and assured through stringent Statistical Process Control (SPC) monitoring of fabrication and assembly processes, material inspection, new product qualifications, the reliability of the finished product and strict change control management.

SPC techniques are used to optimize processes throughout the corporation. The use of Statistical Methods has become an integral part of all of our business practices, including:

• Product Conception

• Product Specifications

• Design and Manufacturing

• Supplier and Subcontractor Management

MANUFACTURING

Our 120,000 Square Foot Facility is Equipped with the Following:

Metal Stamping

• 14 Bihler's

• 30 Punch Presses

• 10 Multi-Slides

Plastics

• 15 Robotic Injection Molding Machines

• 28 Vertical Injection Molding Machines

Assembly

• 9 Sonic Welders

• 10 Vision Inspection Machines

• 30 Sorting Bowls

Manufacturing success requires suppliers to provide quality, consistency, reliability and on-time availability of the product. We are subscribers to lean manufacturing, as well as the 5S workplace organization methodology, which allows us to meet and exceed yield and utilization targets. All parts are manufactured in-house, including tool build capabilities and machine maintenance.

We welcome at any time a review of our production facility so you can see how your parts are being made, demonstrating the procedures we have in place to ensure the quality and value we can add to your product.

CUSTOMER SERVICE