Industry Leaders

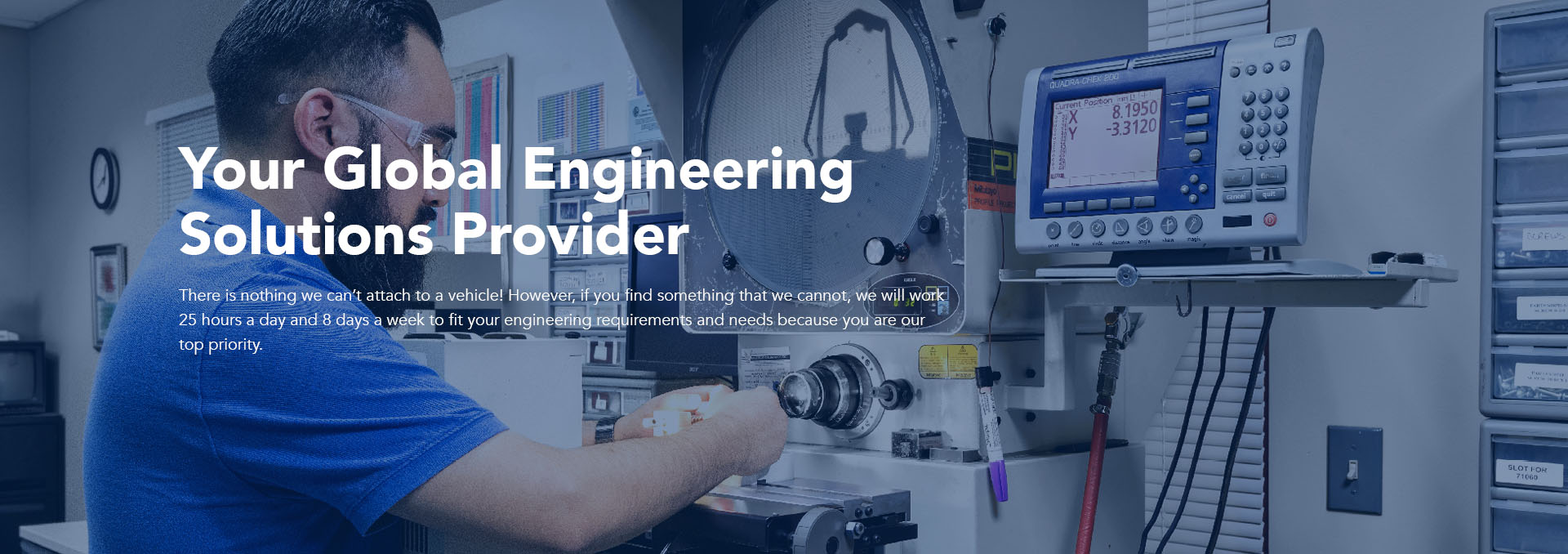

OEM Preferred Fastener Supplier Company, offering a wide selection of metal, plastic and rubber fastening systems.

Superior Quality

Awarded by our customers for Quality Excellence, Platinum Supplier Ranking, and Excellence for Execution.

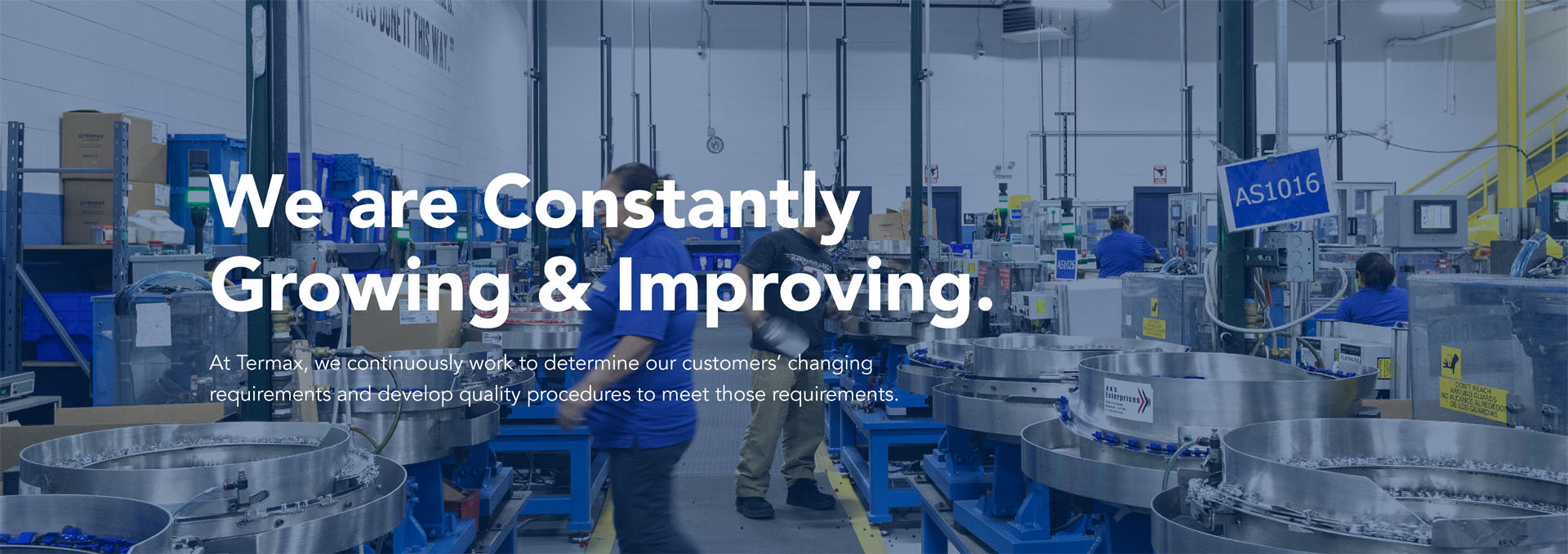

Continuous Growth

Committed to continuous process improvement, expansion of product lines and development of global customer base.

World Class Values

Continuous reinvestment into our business to maintain the world class values that our customers are accustomed to.

Global Footprint

“Footprint” throughout the globe, supported by an International Customer Service team, 25 hours a day and 8 days a week.

Value Added Costing

Adding value into our cost models allows for the best competitive costing solution in the fastener marketplace.

ENGINEERED SOLUTIONS & CUSTOM INNOVATIONS

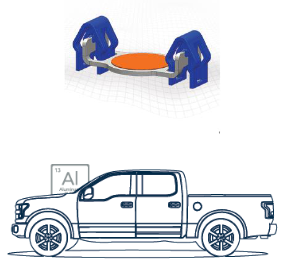

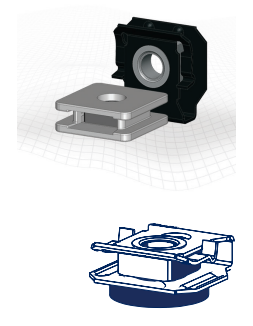

Magnet Plate Attachment

As more and more vehicles have started to use aluminum in the body, Termax has had to develop an alternate way for magnets to be attached. In order to allow for the use of a magnet on aluminum Termax has created a snap in steel plate to be used as a magnetic surface.

Screwless High Retention Clips

Traditionally high retention clips in the vehicle will have a visible screw or screw cap cover. To many, the visible screw and screw cap covers are unsightly. In response to this Termax developed a high retention clip that provides the high extraction without unwanted visible dissatisfiers. This was done by creating high retention clip that would be snapped into a doghouse like a plastic bird's beak, and serviced out of the same feature.

Lock Rod Bezel

This is a plastic sleeve that snaps into the underside of the beltline of the door onto the actual “Class A” lock rod bezel. This sleeve Termax created addressed several issues the “Class A” bezel had on its own:

Improved Retention:

The “Class A” bezel by itself is plastic snaps or fins attaching to a plastic substrate. At times the lock rod would function up and down and pop the “Class A” bezel out of the door. The “Class B” bezel Termax created prevents this from occurring.

Improved Lead In:

The “Class A” bezel by itself has almost no lead in for the OEM operator to fish the lock rod through the door trim during installation. The “Class B” bezel Termax created provides ample lead in for the operators.

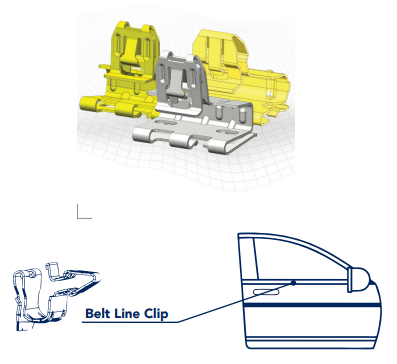

Belt Line Clips

Weld flanges are typically located at the edges of trim parts where key fit and finish measurements are found. The weld flanges are not typically friendly to attachments, but beltline clips have become the exception. By switching the slot from the s/m body to the trim part Termax has created an extremely robust clip solution for weld flange attachments.

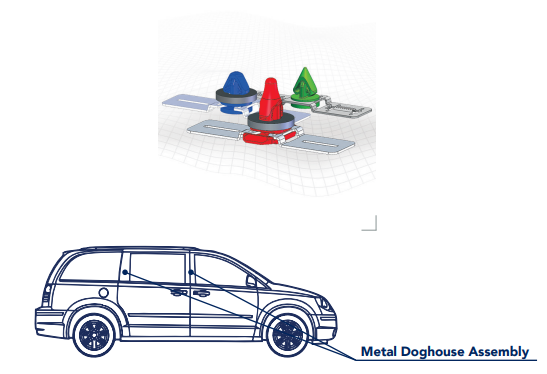

Metal Doghouse Assembly

In applications, such as an exterior B/C Pillar, there is not enough package space to mold a doghouse into the part. In order to eliminate the need for a molded doghouse, Termax developed a low-profile clip assembly that includes a metal doghouse and a plastic clip. This avoids the need for a molded doghouse and instead uses two very small molded ribs.

Locator Cap Clips

It is general design practice to have a locator on all trim pieces. Unfortunately, some customers have found that they do not have the package space to include a locator post and a clip tower. In order to solve this problem Termax developed a clip that combines the locator post with the clip!

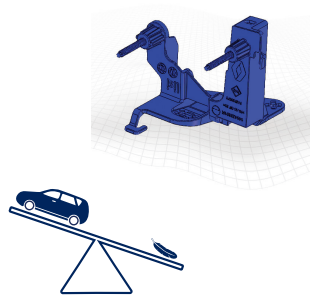

Lightweight Solutions

LISI’s expertise in both metal and plastic technologies is being used at the forefront of light weighting technologies. By taking a current metal component and redesigning it with a structural plastic construction (using a specific blend of glass fiber and plastic), LISI is able to reduce component weights significantly. In some designs it is possible to eliminate complexity by redesigning the fastening strategy.

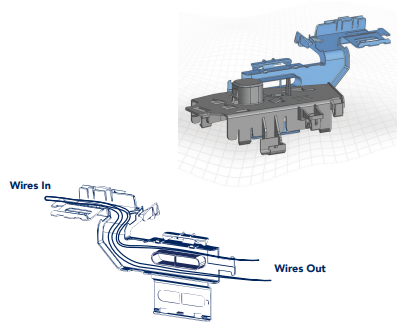

Wire Harness Brackets

Specific wire channel brackets are developed to reduce complexity in the current wire attachment scheme. LISI will combine multiple clips, brackets, and attachments all into one molded bracket. This reduces weight, complexity, and assembly time.

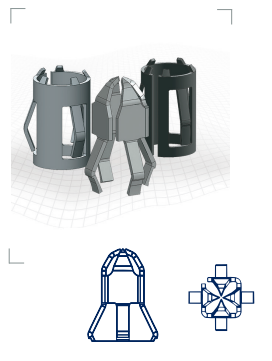

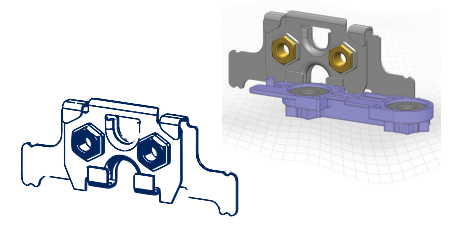

Spoiler Insert Nuts

One challenge with designing a spoiler is the ability to account for the thermal expansion this part experiences. LISI has developed a variety of sliding insert nuts. These nuts are inserted into a doghouse feature to allow them to compensate for thermal expansion and at the same time ensure a secure threaded attachment to the vehicle. These insert nuts also serve as a compression limiter to eliminate damage to the spoiler. Insert nuts are available in a variety of options including plastic, metal, sealing, and non-sealing.

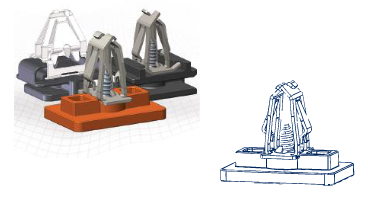

Door Striker Attachment

Door strikers are typically attached to a welded or crimped nut. In order to save assembly time and money, LISI developed a clip in nut for the striker bracket. These door striker attachments are an assembly of a plastic bracket and the nut. An even better advantage of these attachments is they allow for 2 directions of float for gap adjustments.

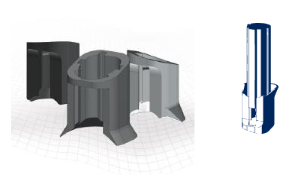

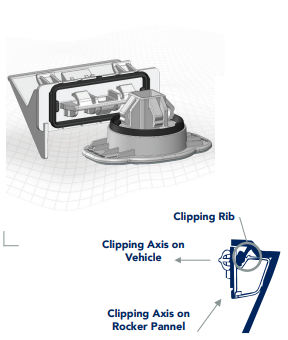

Rocker Panel Clips

Unique rocker panel clips are needed in applications where a molded doghouse is undesirable or is not packageable. Some molded doghouses can lead to visible shrink marks on the rocker panel. LISI has developed these unique clips that attach to a rib on the panel which eliminates the need for a doghouse. Additionally, these rocker panel clips are able to obtain a much higher extraction value, reaching between 180 – 225 LBS.

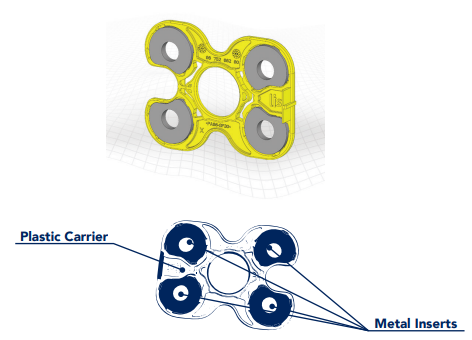

Axle Spacers

Typical axel spacers are completely metal components and are very heavy. In order to promote weight savings in the vehicle LISI developed axel spacers that are a hybrid of plastic and metal. The metal inserts within the plastic carrier can also be swapped out for different thickness, this allows one tool to be used across many platforms which reduces complexity.